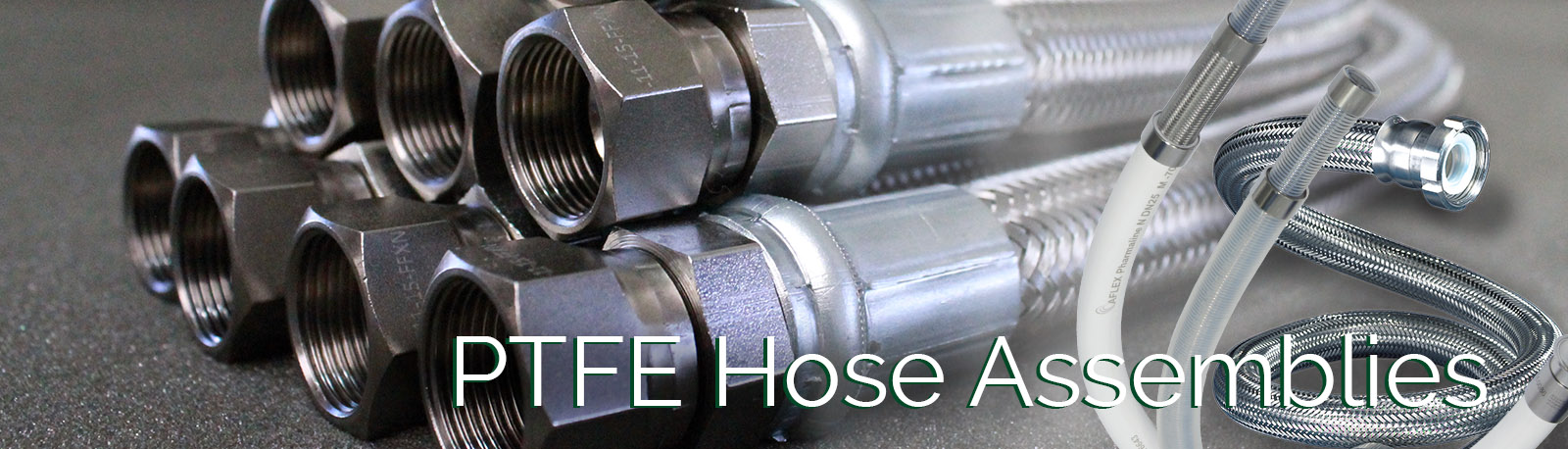

PTFE HOSE ASSEMBLIES

Stainless Steel Braided PTFE Hose & Rubber Covered PTFE

PTFE Hose is a very versatile and durable alternative to rubber hose. PTFE (Polytetrafluoroethylene) is used as a liner for stainless steel braided hose or rubber hose to increase temperature range compatibility, chemical resistance, flexibility and shock resistance. Specific characteristics & high chemical/temperature tolerances make this a popular choice among engineers and facilities managers. At McGill Hose & Coupling, we will closely partner with you and your team to fabricate the best solution for your specific application needs. Choosing the correct PTFE hose fabricator is paramount to achieving the best possible hose assembly for your most critical fluid transfer applications.Key Industries Served:

Pharmaceutical, Automotive, Power Generation, Cosmetics, Chemical Transfer, Food & Beverage.

Our McGill Team of hose and fittings experts welcomes any questions about products or fabrication capabilities. Whether you need a one-of-a-kind special product, high volume products or just need help getting started, you can live chat with an expert on our website, call us at 413.525.3977 or send us an email.

PTFE Hose Features:

- Wide Temperature Compatibility

- Chemical Resistance

- Flex & Shock Resistance

- Steam Compatibility

- Non-Contaminating

- High Flow Rate

- Lightweight

- Resists Deterioration

FEATURED PTFE HOSE TECHNOLOGY:

- Medium Pressure Smoothbore Hose (1/8” – 1-1/4” 3500 psi max)

- Hi-PSI (High Pressure smoothbore up to 5000 psi)

- Industrial Convoluted (3/8” – 2” with extreme flexibility and durability)

- High Purity Convoluted (1/4” – 6”)

- Chemical Hose-Rubber Covered Industrial Hose

PTFE Hose for Food & Beverage Industries

Dissolved oxygen (DO) is a major issue for the food and beverage industries due to the repetitive up-and-down action of food and beverage processing equipment. PTFE and PTFE-lined hose construction is ideal for food and beverage efficient product transfer and handling while simultaneously offering an exceptionally long service life. Its design retains a smooth circular bore without distortion, resulting in smooth, consistent flow with minimal turbulence.

EXPERT PRODUCT SUPPORT

McGill Hose & Coupling brings over 60 years of experience and technical support to meet all of your custom hose and fittings needs!

PFTE HOSE PRODUCTS

MEDIUM PRESSURE SMOOTH BORE

Medium pressure smooth bore Fluoropolymer (PTFE) hose (3000 PSI) features an inner core of PTFE hose reinforced by an outer layer of stainless steel wire braid for strength and protection. This flexible water hose is widely used for a wide spectrum of applications including demanding compressed gas and industrial applications. The low-friction surface of smooth bore hose provides for high flow rates and these hoses are easily drained and/or cleaned. Our custom, precisely machined fittings will result in a truly reliable hose assembly for all of your demanding applications.Rubber Covered – Chemical Hose

Chemical transfer hoses are typically rubber covered polytetrafluoroethylene or PTFE hoses. Chemical hoses (also referred to as chemical transfer hoses) are used to move chemicals from one location to another. These hoses are manufactured from materials that are highly chemical resistant. Rubber covered polytetrafluoroethylene or PTFE hoses are used in applications such as transferring acids, solvents, and petroleum products to or from storage containers in industrial plants and are also used for spraying pesticides, fertilizers, and paint. Bulk chemical hoses can be cut to the desired length and compatible chemical resistant hose fittings(Coupling alloy and gasket must be compatible with chemical being transferred) can be added to the ends of the hoses to create custom hose assemblies. Chemical hoses are FDA approved per 21CFR177.1550, US Phamacopeia Class VI, 3-A Sanitary Standard 62-01.

Featured Product:

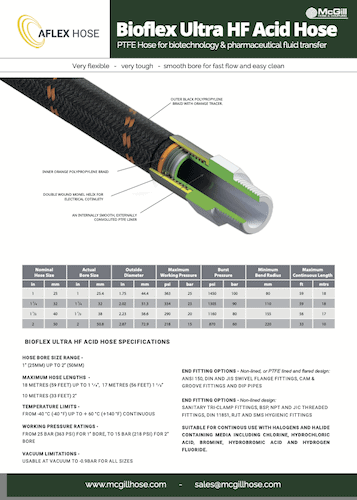

AFLEX Bioflex Ultra HF Hydrochloric Acid Hose

Hydrochloric Acid Hose

PTFE Hose for biotechnology & pharmaceutical fluid transfer. Very flexible – very tough – smooth bore for fast flow and easy clean.ANTI-STATIC/CONDUCTIVE HOSE

A safe solution where static can build up in especially high flow rate applications. Static can be very dangerous in hose applications by jumping through the tube to the braid and cause failure if a conductive hose is not used. When using flammable media, if a standard, non-conductive hose is used static could ignite the media. By using a conductive hose, it will facilitate transfer of the static charge to the end fittings and ground.CONVOLUTED

Convoluted PTFE hoses are manufactured with smooth, rounded, helical shaped convolutions which help to promote easy cleaning and self-draining for the ultimate high purity, convoluted hose. Key features of convoluted hoses are that they are lightweight and their flexibility provides a superior flex life.

High Pressure / HI-PSI PTFE HOSE

Hi-PSI hose is needed in applications where high and low temperature, chemical resistance, low coefficient of friction, flexibility, and non-aging characteristics are required. Hi-PSI Series hose is a heavy wall hose for very high pressure applications and the reinforcement is braided and not spiraled allowing for better hose flexibility.Process Hose

Flouropolymer Tubing

Fluoropolymer material is recognized for heat tolerance — up to 500°F continuously. It also excels at performing in extremely cold temperatures. With few exceptions, fluoropolymer tubing can handle virtually any corrosive chemical in use today – including solvents, acids, and bases.PTFE HOSE BRANDS

- Bioflex Ultra

- Pharmaline N,X

- Corroline +

- Corroflon

- Smoothbore Assemblies

- Convoluted Hose Assemblies

- Hyperline FX

- Versilon

- FaBLine

- Medium Pressure Smoothbore PTFE

- S-Series, SC-Series, S-TW Series

- Industrial Convoluted

- 8000 Series, 8500 Series

- Medium Pressure Smoothbore PTFE

- R115/R122

- R105/R144

- Industrial Convoluted

- R272/R276

- R285/R287

- High Pressure

- R165

- R154

- Versilon® FEP and PTFE hose

- TLCT, TLCTO, CTLCT, WCLCT

- TWOB, TBOB, TWOBHV, TBOBHV

- WCS, WCSS

- T1167

- T-1794

- UltraFlex

- MultiFlex

- FlexChem

- VersaChem

- Hi-Per