Hydrostatic Testing

One of the most common tests performed at McGill Hose & Coupling is the Hydrostatic hose test. In these tests hoses are filled with water then pressurized in accordance with either the NAHAD standards (usually 1 and a half times working pressure) or in some cases where the customer requires a more stringent test even higher pressures to ensure that the hose assembly is assembled safely and reliably and will exceed performance needs in the field. While it is rare to have a hose assembly leak when testing, it is much better to find out about a manufacturer defect or installation issue before the hose is in the field.

Pneumatic leak testing

Hose assemblies that we make can also be tested with inert gasses such as compressed air, Nitrogen and Helium. We most often perform these tests on our Metal Hose assemblies which are 100% tested with Nitrogen underwater test to confirm that all welds are sealed completely. These tests can also be important as gas molecules may find smaller leak paths than hydrostatic test can detect. This common standard test is performed underwater and the test is a pass if no gas bubbles are detected over a given period of time, at least 20 seconds, or long enough to confirm that all fabricated (welded) connections are leak free. This time can be extended as specified to meet the test requirements of our customers.

Helium Mass Spectrometer testing

When the application demands ultimate confirmation that there are no leaks in a fabricated hose assembly. We offer Helium leak testing with Mass Spectrometer detection of even the smallest (sub -microscopic) leaks. Helium is the smallest of the inert gas atoms, and as such it will find leaks smaller than the other pneumatic leak tests. By employing a Mass Spectrometer we can confirm that even minute amounts of Helium (smaller than would be visible with the naked eye as bubbling) are not escaping hoses. This test is performed by personnel with specialized training on routinely calibrated equipment. This stringent test ensures maximum safety for our customers with dangerous and volatile applications, especially those working with fuel cells where the smallest leaks can be explosion hazards.

BURST TESTING

At McGill Hose & Coupling we routinely test hoses to the point of bursting, in some cases over 20,000 PSI. This allows us to demonstrate proof of safety. In most cases our hoses will have a safety factor of 4 to 1. This means that the working pressure should be one quarter of the bursting pressure of the hose. Our extensive combinations of hoses and fittings makes our ability to test and confirm bursting pressures invaluable. Otherwise we would have to rely on hose and fitting manufacturers’ data for our customers’ safety with some of our custom fitting solutions.

Electrical/Conductivity testing

Hoses that carry flammable media, or operate in environments where static discharge can be a safety concern need to make sure that their hoses are not only the right type, but also assembled correctly and tested to confirm that they won’t pose a safety concern. If a chemical hose or fuel hose carrying flammable media isn’t properly grounded from end to end, then static electricity can build up and spark causing fire and explosion. When we assemble hoses for these applications and others which require end to end conductivity we have a 100% grounding protocol to ensure the hose is safe to use. We can provide test certification upon request for these hose assemblies giving piece of mind that you and your team are protected.

We also routinely test customers’ hoses in the field or in house to confirm that they are still safe after they have been in extended service. Use and abuse can lead to breaks in the grounding wire and it is important that this be detected and the hose be removed from service.

Re-testing + Certification

The life of a hose assembly can be extremely demanding and as such it is important to have a periodic testing schedule for hose assemblies that are being used for long periods of time, or under the most demanding conditions. Hose failure is dangerous, even deadly we help provide a way to protect our customers from harm and failure related damages by being able to test hoses either in the field or at one of our three branch locations. Equipment rental companies take advantage of this service regularly to ensure that their equipment is going out and coming back in safe working condition. We can even recommend testing schedules based on the application and the hose selected.

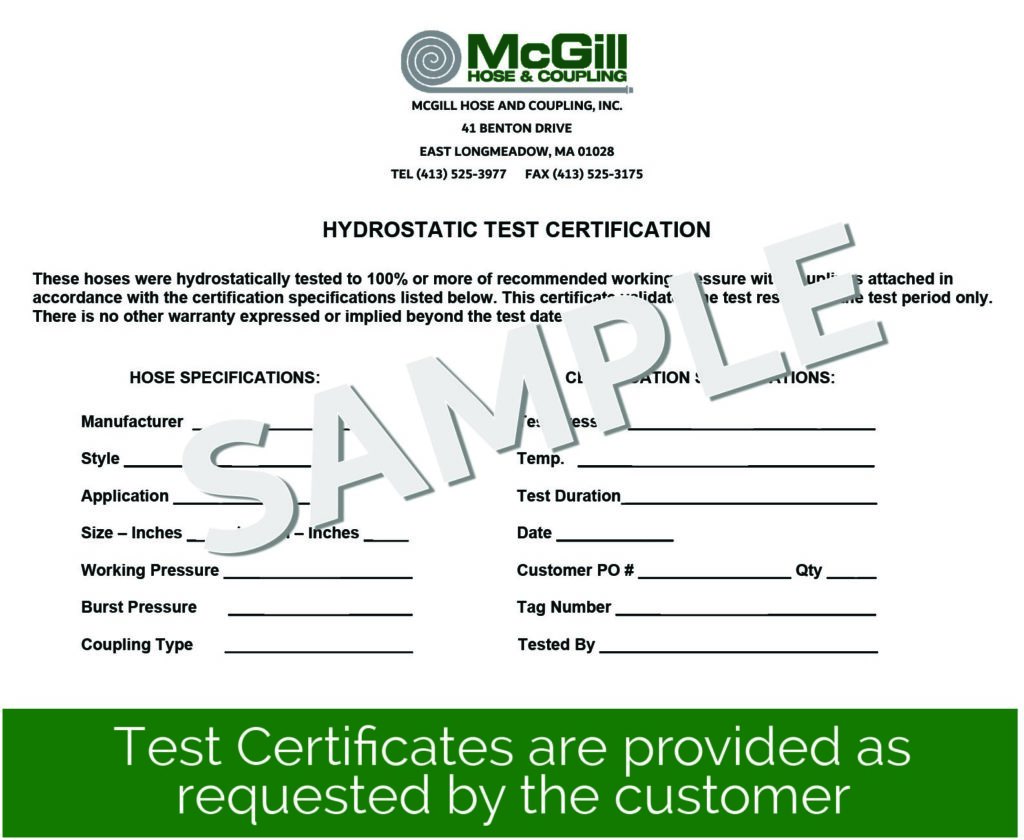

Certification of hose assemblies that have been tested prior to delivery, or after a period of service gives our customers piece of mind and documentation that they take safety seriously and that test have been performed in accordance with established hose safety standards. Youre safety is always our first concern.