Steam Hoses, Steam Fittings & Crimped Steam Hose Assemblies

Steam Hoses are highly temperature resistant hoses used to safely transport steam and hot water for cleaning and other purposes in industrial applications. They are designed to sustain high temperatures and offer flexibility for easy handling. Steam hose also typically has a very long lifetime due to it’s durability.

Crimped Steam Hose Assemblies

Watch this video to learn more about the high standards McGill Hose & Coupling utilizes to ensure your steam hose assemblies are built to the highest standards – using the best quality steam hose and fittings products available – fabricated to the highest standards in the industry!CONTI® BLUE STEAM Hose

Label:

“Continental CONTI® BLUE STEAM FDA Glas-/Gabel-Symbol BfR EG 1935/2004 2023/2006 Made in Germany”ADDITIONAL FEATURES

- 2 years warranty

- Recommended fittings system DINGA® water saving gun for hot water applications

- Safety factor steam ≥ 10, hot water ≥ 3

- Suitable for steam fittings according to DIN EN 14223

- Working pressure up to 20 bar (290 psi) at 95°C up to 6 bar (87 psi) at 164°C

- WORKING PRESSURE UP TO 20 bar / 290 psi

- TEMPERATURE RANGE from -30 °C / -22 °F up to +95 °C / +203 °F

- DAMPABLE UP TO +164 °C / +327 °F up to 6 bar / 87 psi – open system only

Standard/Approval Ratings:

FDA: Regulation 177.2600 BfR: Recommendation XXI, Cat. 2 EU: 1935/2004 2023/2006APPLICATIONS

Cheese dairies, Dairies, Foodstuff industryFLOW MEDIUM

Hot water, SteamINNER LINING

EPDM, FEP, white, neutral to taste and odor, non-porous, smoothREINFORCEMENTS

Synthetic fibresCOVER

EPDM, blue, orange, fabric patterned, abrasion resistant, resistant to ozone, weather and UVCRIMPED STEAM ASSEMBLY

Applications:

Coupling assembly crimps permanently onto hose; forms a tight crimp that reduces leaks and eliminates bulky bolt clamps while reducing potential for damage from snagging on personnel or property.Specifications:

Construction Tube: Chlorobutyl synthetic rubber, EPDM, & black Pyrosyn® Cover: Red or black EPDM synthetic rubber, black or red Pyrosyn® finish (pin-pricked), red wrapped Pyrosyn® (pin-pricked) Reinforcement: Braided Steel Wire Coupling: Female Ground Joint Low Profile, Female Ground Joint Wing Nut, Male NPT, Male NPT Swivel, & Female Spud crimped fittings are availableDAMPF TRIX® 6000 Steam Hose

Label:

Continental ContiTech DAMPF TRIX® 6000 – DAMPF / STEAM – PN 18 BAR / 261 PSI – Ω Made in GermanyApplications:

DAMPF TRIX ® 6000 high-temperature resistant steam hose can handle the most severe working conditions for conveying saturated steam in the chemical and petrochemical industry, in refineries, the building industry, in shipyards and for various other industrial applications. It is made of an extremely heat resistant EPDM lining and cover assuring the transport of pure, saturated steam at +210°C and 18 bar, or even at +220°C and 23 bar for short-time service. DAMPF TRIX ® 6000 is manufactured to European standards. Design Factor: 20:1 for < 1” ID hose and 10:1 for > 1”Specifications:

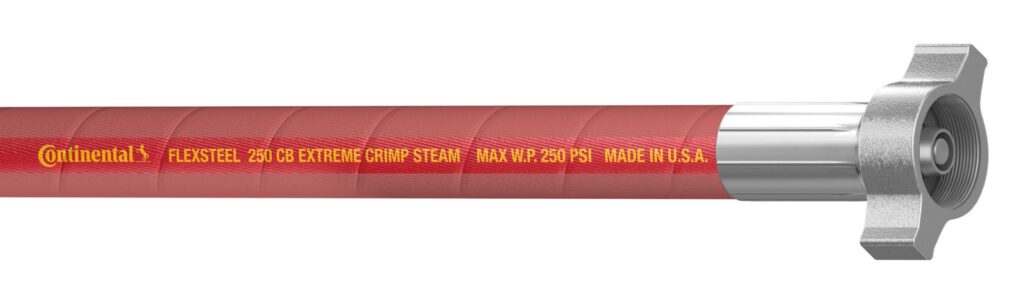

Construction Tube: Black, non-porous, smooth, conductive, EPDM lining Cover: Black, conductive, fabric patterned EPDM-cover, resistant to ozone, weather, UV and abrasion. Reinforcement: Dual steel wire braids Temperature Range: -40°F to 410°F (-40°C to 210°C)Flexsteel® 250 CB Extreme Crimp Steam Hose

LABEL:

CONTINENTAL CONTITECH FLEXSTEEL® 250 CB EXTREME CRIMP STEAM, DRAIN AFTER USING, MADE IN USAAPPLICATIONS:

Flexsteel® 250 CB Extreme Crimp Steam Hose IS the only ContiTech chlorobutyl steam hose with an enhanced over the cover crimp coupling solution. Features a 10:1 safety factor.SPECIFICATIONS:

Construction Tube: Chlorobutyl synthetic rubber Cover: Red or black Pyrosyn®, pin-pricked Reinforcement: Two-braid steel wire Temperature Range: -40°F to 425°F (-40°C to 218°C)Flexsteel® 250 CB Steam WF (Wrapped Finish) Steam Hose

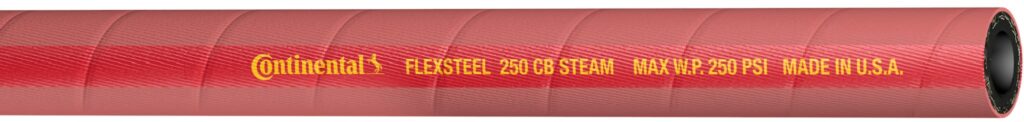

LABEL:

ContiTech Flexsteel® 250 CB Steam Max WP 250 PSI. Made in USAApplications:

Flexsteel® 250 CB Steam WF steam hose is used in cleaning, heat control, fire prevention, pumping, thawing, blowout service, steam pumps and hoists in open-end or permanent installation operations. This hose is often used in refineries, shipyards, chemical plants, steel mills, foundries and heavy industrial applications where high strength is required for severe environmental conditions.Specifications:

Construction Tube: Chlorobutyl synthetic rubber Cover: Red or black Pyrosyn® synthetic rubber Reinforcement: Braided steel wire (3/4” and higher have 2 steel wires). Coupling: Contact McGill Support for proper fitting recommendation and coupling procedure. Temperature Range: -40°F to 425°F (-40°C to 218°C) Packaging: Wrapped cover: – 1/2”, 3/4”– 1” – Three 50’ exact length/box, 1 1/4”– 2” – One 50’ exact length/boxFlexsteel® 250 EPDM-20 Steam Hose

LABEL:

Continental Flexsteel® 250 EPDM-20 W.P. 250 PSI. Made in USAApplications:

Flexsteel® 250 EPDM-20 steam hose features the superior performance of Flexsteel 250 Steam hose series enhanced with the increased safety factor of 20:1. This exceeds the ARPM safety standard and makes steam operations more secure and user friendly. The hose has a maximum operating pressure of 250 PSI.Specifications:

Construction Tube: Black Pyrosyn®, pin-prickedCover: Red wrapped Pyrosyn®, pin-pricked Reinforcement: (2) braided wire Coupling: *(Ready 2 Go logo)- Coupled assemblies available. Temperature Range: -40°F to 450°F (-40°C to 232°C)

Flexsteel® 250 ORS Steam Hose

LABEL:

Continental ContiTech 3/4″ Flexsteel 250 ORS Steam Made in USA Drain After UsingAPPLICATIONS:

Flexsteel® 250 ORS Steam Hose offers all the performance and features of the Flexsteel® 250 Steam with the added benefit of improved oil resistance in the cover. Excellent for steam hose applications where the cover may be exposed to oil. Applications include; cleaning, heat control,fire prevention, pumping, thawing, blow-out service, steam pumps and hoists in open-end or permanent installation operations. Often used in refineries, shipyards, chemical plants, steel mills, foundries and heavy industrial applications where high strength is required for severe environmental conditions.Specifications:

Construction Tube: Black EPDM Cover: Wrapped black oil-resistant synthetic rubber, ARPM Class B (Medium Oil Resistance), pin-pricked Reinforcement: Two-braid steel wire Coupling: Please consult a McGill Hose Coupling Expert for crimp specifications. Temperature Range: 0°F to 425°F (-18°C to 218°C) Packaging: Reels or 50′ cut lengthsHeavy Duty Steam Pile Driver Hose