Custom Tube & Pipe Bending Services

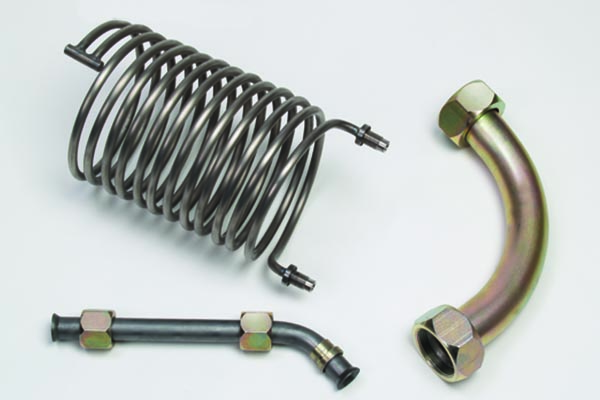

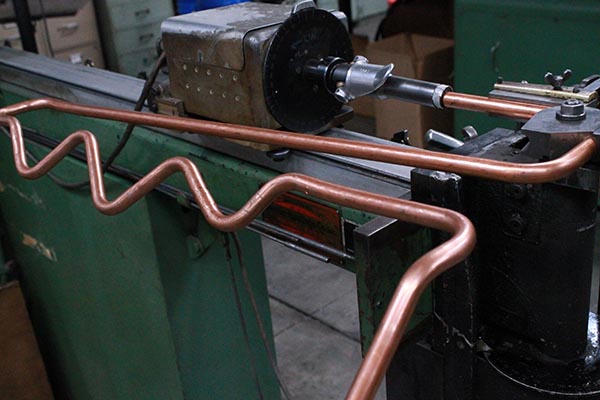

McGill Hose & Coupling, Inc. is experienced in both simple and complex bends to offer another dimension of fluid handling solutions. Whether a single prototype or production bends, our commitment is to accuracy and quality.We offer custom tube and pipe bending, as well as forming, flaring, welding and plating in Steel, Stainless Steel, Copper and Aluminum. Some of the more exotic specialty metals like Inconel and Hastelloy can be sourced as well.

Our knowledgeable staff would be happy to discuss our specific capabilities if you have an application we could assist with.

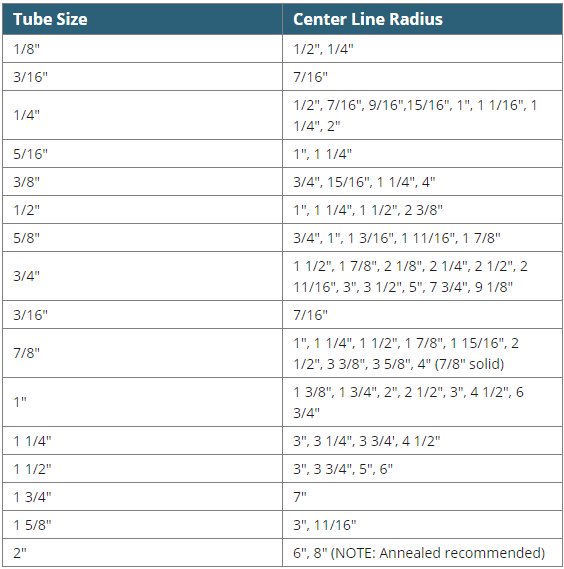

TUBE BENDING CAPABILITIES

- Round Tube: 1/8” to 2” O.D. NOTE: Aluminum tube, pipe, and rigid copper should be annealed before bending.

- Square Tube: 5/8”, ¾”, 1” with limited dies

- Solid Bar: 1/8” to 1.062 O.D. NOTE: Angle Iron – Limited dies. Consult tube bending department.

- Rectangle Shapes: We have the tooling for ¾” x .065 and bent the hard way.

- Pipe Threading: 1/8” to 2” pipe. Prototype and Production runs.

- Pipe Bending: 1/8”, ½”, 3/4”, 1” NOTE: We can have dies made up to 1 ¼” pipe.

- Flaring:

- Flare: 37.5° JIC Flare 3/16” – 2” O.D.

- Flare: 45° JIC Flare 3/16” – 1” O.D.

- MIG

- TIG

- Plasma Cutting

- ASME B31.1 Certified

- Custom made hose-end fittings

- Custom Manifolds

HYDRAULIC TUBE ASSEMBLY DUPLICATION

- Copy original design

- Make improvements in material, routing, upgrades such as routing clamps, brackets, and customization to ensure long service life

- On-site measurement and design when it isn’t convenient to bring in your old assembly or when there isn’t one to copy.

BENDING TO DESIGN DRAWING OR SCHEMATIC

- Work from your drawings and bend tubing to match

- Original Equipment customers trust us with their critical tube needs.

- Work with engineers on their designs for projects in development.

DESIGNING SOLUTIONS

Tell us what you want to accomplish and we can put our experience to work for you in designing and bending a tube assembly that will provide a lasting solution.

CUSTOM STRUCTURAL ASSEMBLIES

Our bends are not just for pneumatics and fluid conveyance, we make structural assemblies from round tube, square tube, and rod stock.