Industrial fluid systems have dozens of hoses that control the flow of critical fluids from one part of the system to another. Putting mission-critical data on tags can help prevent significant downtime.

By Brian Aplin, Field Engineering Supervisor, Swagelok Company

To service hoses in flow control applications properly, technicians often need to get answers to questions such as:

- What types of fluids are being transferred?

- Are those fluids at high pressures or temperatures?

- Are they potentially hazardous?

- How long has each hose been in service?

- What materials are the hoses made of? What sort of replacement is necessary?

For scheduled maintenance or in the event of a failure, the technician must identify the answers to these questions, which may involve referencing the system’s schematics. During this time the system must be shut down to prevent potential leaks from occurring. This additional downtime can potentially hurt production and reduce profits of the systems involved.

Fortunately, unplanned downtime can be reduced by tagging all parts of a fluid system, even those deemed less essential. Tags provide technicians access to mission-critical data more easily which allows for more effective preventive maintenance and reduced system interruptions, see Figure 1. In the end, it allows maintenance programs to run more efficiently and helps to keep plants operating at peak performance.

Figure 1: Tagging hoses in your system can provide mission-critical data to technicians enabling more effective decisions.

Start With a Plant Audit

The most effective hose tagging programs begin by understanding what components exist within a plant. Typically, this involves implementing a full plant audit that identifies each hose, noting the type, part number, process fluid, pressure or temperature ratings, and vendor names and contact information in a spreadsheet.

Once this initial information is logged, then it is time to provide additional details. In the case of hoses, that can include the length, size, core material and construction, reinforcement layers, end connections, and mounting. It may also include cover type, operating conditions, cleaning procedures as well as the date the hose was installed and when it is scheduled for replacement. This information will form the basis of the tagging program.

Figure 2: Avoid unnecessary downtime and potential errors caused by additional system and component research by tagging hoses in the system.

Tagging Leads to Proactive Maintenance

Although most plants do tag major fluid system components, hoses are sometimes overlooked. Placing tags on these components can often reduce the amount of time it takes for technicians to identify if and when a component needs to be replaced, see Figure 2. Proper tagging will offer technicians’ information such as when the hose was last installed, what its core material is, and what fluid it is carrying. Knowing this essential data provides insight into when maintenance on the components is necessary before they completely break down, causing a systemwide shutdown for repairs.

Tagging can also be used to alert technicians to problems with the equipment that have developed onsite. These insights provide a full maintenance history to technicians and may allow them to troubleshoot smaller issues before they become systemwide.

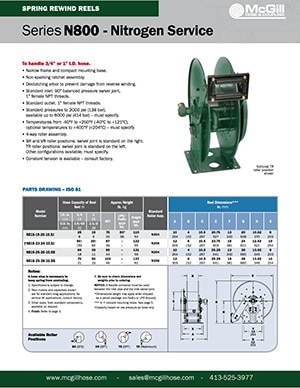

Figure 3: To enhance the effectiveness of tags include:

• Part Number

• Date of manufacture

• Trace identification number

Additional information that can be included on the tag:

• System media

• Operating pressure

• Operating temperature

Efficiency Is Improved with Proper Information

Though tagging allows for easy identification of components and provides essential maintenance data, tags are only as effective as the information they contain, Figure 3. At minimum, tags should include the part number, date of manufacture, and the trace identification number so it can be tracked to its initial order. Additional information that can be included on the tag includes system media, operating pressure, and temperature.

In most cases, this information can be obtained from the component manufacturers themselves. Often, they will also supply specific tag styles that correspond with the individual plant’s needs or those of the industry. Some suppliers offer everything from simple metal tags to color-coded tags that wrap around the hose. Color-coding the tags allows workers to immediately identify the types of fluids or gases that are flowing through them, which reduces the chances of an error being made.

The amount of information that can be included on the tags will depend on the tag style and size. For instance, a typical tag contains approximately five lines of text with room for roughly 25 characters per line. If the plant requires it, tags can be coated with silicone to keep contaminants out and make cleaning them easier. Having this information readily available allows maintenance technicians to service their systems more easily and efficiently, Figure 4.

Figure 4: Technicians can add information each time a hose is serviced, making future maintenance easier and enabling the operator to trend issues with the system.

Tags Tell the Story

In the end, tagging all the elements of an industrial fluid system will reduce the amount of downtime the system requires; maintenance technicians will not be searching for schematics or doing research. Instead, they will have the necessary information readily available that will allow them to take preventive action to keep the system always operating at peak performance, which will improve the plant’s bottom line, Figure 5.

If you are interested in how to create a full tagging system for your facility, start by consulting with your component supplier. They should be able to advise you on the best system for your specific applications to expedite maintenance, improve system safety, and reduce unnecessary downtime.

Figure 5: Maintenance becomes more effective and efficient with detailed information at the maintenance team’s fingertips.

ABOUT THE AUTHOR

Brian Aplin is Field Engineering Supervisor for Swagelok Company.