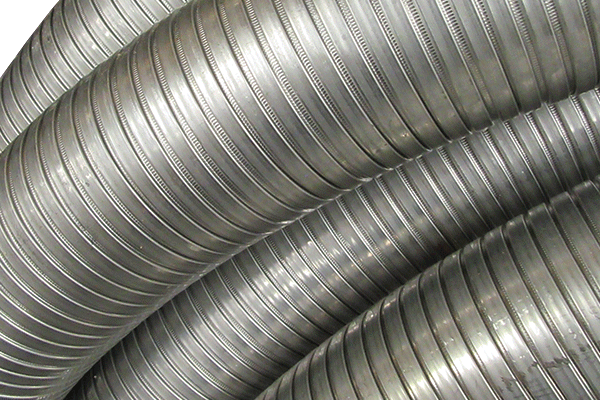

Stripwound Metal Hose Assemblies

Stripwound Metal Hose, is a flexible metal hose that is ideal for the transfer of abrasive materials. Although it is not gas tight, like corrugated hose, it is durable, and an excellent choice for use as a guard, an open-ended exhaust hose, and for the transfer of dry bulk materials. It is also used in some water & wastewater treatment applications. One of the main benefits of stripwound hose is its ability to not contaminate the transferred product with any residue.Our McGill Team of hose and fittings experts welcomes any questions about products or fabrication capabilities. Whether you need a one-of-a-kind special product, high volume products or just need help getting started, you can live chat with an expert on our website, call us at 413.525.3977 or send us an email.

Benefits of Stripwound Metal Hose:

- Withstands extreme temperatures

- Chemical compatibility-either internally or externally

- Abrasion and over-bending concerns

- Potential for catastrophic failure- If a sudden hose failure would be catastrophic to your operation, a metal hose may minimize the damage by leaking product at a slower rate.

- Fire safety: Other hose types can melt when exposed to fire or high temperatures. Metal hose, however, maintains its integrity to 1200 ̊ F and beyond.

- Full vacuum applications: Metal hose maintains its shape even under full vacuum – a condition where other hose types may collapse.

- Fitting configuration flexibility: Virtually any type of fitting can be attached to metal hose, without the special shanks and collars needed with other types of hose.

Common Applications for Stripwound Metal Hose:

- Pneumatic plastic pellet transfer systems

- Portable grain vacuum systems

- Biomass transfer systems

- Aggregate transfer in asphalt plants

- Powdered cement transfer

- Powdered gypsum transfer

- Chemical powder transfer

- Catalyst transfer

- Material loading and unloading

- Hot air blower hoses

- Rail car loading and unloading

- Dry bulk transloading facilities

- Barge loading and unloading

- Grain transfer

- Pigment transfer

- Carbon black transfer

- Fly ash conveying

- Lime injection systems

- Dust collection

- Wood chip conveying

- Sawdust conveying

- Water & Wastewater Treatment applications

EXPERT PRODUCT SUPPORT

McGill Hose & Coupling brings over 60 years of experience and technical support to meet all of your custom hose and fittings needs!

CUSTOM STRIPWOUND METAL HOSE ASSEMBLIES

Quick Turn Around- Expert Product Support- In House Fabrication Custom Metal Hose Assemblies are our specialty. We complement our metal hose fabrication with an in-house machine shop for special fittings and our tube bending facility for special shapes for hard to reach connections. We can quickly and accurately work from concept, to design, to final ready to use assembly. Within McGill Hose in-house fabrication facilities, our ASME IX B31.1 welders have the ability to custom produce assemblies that can replace OEM parts that are no longer available, provide a better alternative to inefficient setups, or even help with one off needs and build to spec.S.T.A.M.P.E.D: TO SELECT THE RIGHT HOSE FOR YOUR CUSTOM HOSE ASSEMBLY

Although many metal hoses look the same, there are many critical questions to ask and factors/characteristics to consider in order to design the best custom hose solution for your specific application. To properly design a metal hose assembly for a particular application, the following factors should be considered:- Size – I.D. O.D. and length

- Temperature – Internal and external temperatures to the assembly is exposed to.

- Application – Current hose used or discuss equipment and applications hose is intended for.

- Material – Identify all materials/chemicals to which each component of the assembly will be exposed to, both internally and externally. Pressure – Identify the working and vacuum pressure.

- End Fittings – Identify the necessary fittings and custom ends.

- Delivery – Lead Time, Quantity, Special Marking or Packaging Requirements.

Selecting the Stripwound Hose Type:

Choose the most compatible alloy for the service and environment in which the hose will be installed. Then, based on your requirements, choose a strip thickness. The thicker the steel strip, the better the hose is suited for heavier duty. Finally, determine if you need packing and, if so, which packing best suits your application.Types of Stripwound Hose:

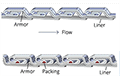

There are four different types of stripwound hose. When selecting you should first decide the most appropriate type of hose (squarelocked, interlocked, smoothbore interlocked) and then select the one best suited for your specific application. Roughbore Interlocked – The strip is formed with legs that interlock to form a tighter, more rugged construction. Features & Benefits: Extremely flexible. Ideally suited for conveying dry, bulk materials, for open-end gas exhaust, and as a protective cover.Smoothbore Interlocked – Made by adding another steel strip inside a roughbore hose to provide a smooth surface, thereby reducing damage to sensitive materials. Features & Benefits: Extremely flexible. Ideally suited for dry bulk conveying.

Packed Interlocked – Packing may be added to interlocked hose to minimize leakage through the hose profile. Features & Benefits: The most effective packings are made from resilient materials such as elastomers and, to a lesser extent, cotton. Harder materials (stainless steel and copper) are also available if required.

Squarelocked – The strip is formed into square shapes that are locked together. Features & Benefits: Extremely flexible. Primarily used as a protective covering for wires, fiberoptic cables, and other hoses.

Flexible Stripwound Metal Hoses Offered:

INTERFLEX (Roughbore) Hose

INTERFLEX (Roughbore) is a high-quality, general-purpose hose, constructed from a single strip of metal that is profiled and locked onto itself. The interlocked, or overlapping, sections of strip are able to slide back and forth, providing the ability to flex.

T-REX™ (Roughbore) Hose

T-REX™ (Roughbore) is Hose Master’s torque-resistant stripwound metal hose with enhanced sealability. T-Rex™ provides resistance to twisting, unwinding, and metal strip flare-up when cut.

Ultraflex (Smoothbore) Hose

Ultraflex is a smoothbore metal hose ideally suited for dry bulk pneumatic conveyance. This hose is produced with a durable armor and a highly abrasion-resistant liner. Hose Master’s precision manufacturing process makes Ultraflex unequaled in strength and flexibility.

T-REX™ SB (Smoothbore) Hose

T-REX™ (Smoothbore) is Hose Master’s torque-resistant stripwound metal hose with enhanced sealability. T-Rex™ provides resistance to twisting, unwinding, and metal strip flare-up when cut.

FloppyGuard™ (Interlocked) Hose

FloppyGuard™ (Interlocked) is Hose Master’s line of floppy interlocked metal hose. Constructed from T304 or T316 stainless steel, this product offers flexibility, strength, durability, and crush resistance.

FloppyGuard SQ™ (Squarelocked) Hose

FloppyGuard SQ™ (Squarelocked) is Hose Master’s line of squarelocked stripwound hose. It can be used in a wide variety of applications where the added flexibility of squarelocked hose is required. It is used as shielding on electrical wiring and fiber optic cable.